Specialist Services has successfully completed the 20 man accommodation extension project awarded by SBM

On 2nd May 2013, SBM awarded Specialist Services the contract for EPC works for the 20 Man Accommodation module to be installed on a Floating Production Storage and Offloading (FPSO) for deep-water exploration and production offshore Brazil.

On 2nd May 2013, SBM awarded Specialist Services the contract for EPC works for the 20 Man Accommodation module to be installed on a Floating Production Storage and Offloading (FPSO) for deep-water exploration and production offshore Brazil.

Project: 20 Man Accommodation Module for BC-10 ESP Rig-less Intervention System (RIS) Project

Client: SBM Malaysia

End User: Shell Global

Location: Victoria, Brazil

Project Completion: 19th September 2014

Project requirements

SBM had been awarded a project for the implementation of a vertical intervention approach utilizing a purpose built intervention facility mounted on to the BC-10 FPSO production facility. The function of the Rig-less Intervention System (RIS) is to facilitate replacement of worn or failed caisson based artificial lift systems deployed in the BC-10 field.

In order to facilitate the above, an additional modular accommodation for 20 persons was required and SBM awarded the project to Specialist Services. The scope of work included engineering, construction, outfitting, installation of equipment, testing and pre-commissioning of the 20 man modular accommodation. The project was required to be installed on the FPSO meeting the necessary interfaces with the existing accommodation block as well as the vessel itself.

Solution

The 20 man accommodation extension was engineered as five separately constructed but formable A60 rated modular accommodation units, each comprising two 2 man cabins with individual toilet / shower facility, split A/C unit, lockers, life jackets, desk, chair and a sofa. The project also included the supply of a sewage treatment plant module (STP), a potable water skid, a 1 meter high master skid as a foundation for the accommodation and STP modules, a walkway enclosure to protect the entrance walkways against blast and vertical and horizontal bumpers to facilitate installation offshore.

In line with SBM’s requirements, the modular accommodation has been designed and manufactured taking into account the essential interfaces between the unit and the existing accommodation block as well as between the unit and the vessel. Considered interfaces included fresh water, sewage, ventilation, electrical power and control systems, personnel access, fire detection and safety.

The accommodation unit is A60 certified with the design review and product certification approved by ABS. The modular accommodation with all installed equipment is compliant with:

- Hazardous Area Classification – Class I Zone 2, Gas Group IIA

- Brazilian regulatory compliance (NR13, NR 30 and NR 10)

- ABS class rules Guide for Crew Habitability on Offshore Installations

- Bahamas regulations on crew accommodation

- IMO resolution A.468 (XII), SOLAS Chapter III Regulation 9

Conclusion

The project required complex engineering, coordination and construction due to the specific requirements related with existing interfaces and characteristics of the FPSO production facility. A number of specification and design changes were requested by the end user, which required additional works for vertical and horizontal bumpers, Telecom / PA system installation, walkway enclosure and other elements that were added to the contract during the project execution.

The pre-commissioning of the installed systems lasted around 50 days under close vigilance and inspection by the end user deployed in Specialist Services yard in Abu Dhabi. After successful site acceptance test of the accommodation module by SBM and Shell, the module was weighed and loaded out from the waterfront facility in Mussafah, Abu Dhabi on 19th September 2014.

The modules are planned to be installed and integrated on the Shell Global BC-10 FPSO Espirito Santo, Brazil offshore by March 2015.

The accommodation modules will cater to meet the additional capacity of persons that will be on board during the intervention function of the RIS on the BC-10 field.

Specialist Services has recently become Achilles Power & Tech accredited. This means that we are now a registered supplier in the Achilles Power & Tech Community for the following products / services:

Specialist Services has recently become Achilles Power & Tech accredited. This means that we are now a registered supplier in the Achilles Power & Tech Community for the following products / services: This accreditation also means that Specialist Services information related to the following criteria has been checked and validated by Achilles Information Limited, an independent third party:

This accreditation also means that Specialist Services information related to the following criteria has been checked and validated by Achilles Information Limited, an independent third party:

Our environment management initiatives are based on systematic environmental impact assessments, which form the basis of our Environmental Management System certified to ISO 14001:2015 standard. We use resources and energy in a responsible manner and reuse or recycle wherever possible. We are committed to manage waste effectively, prevent pollution, use environmentally friendly material and apply our technical abilities for the reduction of our environmental footprint, particularly in the design and engineering of our products.

Our environment management initiatives are based on systematic environmental impact assessments, which form the basis of our Environmental Management System certified to ISO 14001:2015 standard. We use resources and energy in a responsible manner and reuse or recycle wherever possible. We are committed to manage waste effectively, prevent pollution, use environmentally friendly material and apply our technical abilities for the reduction of our environmental footprint, particularly in the design and engineering of our products.

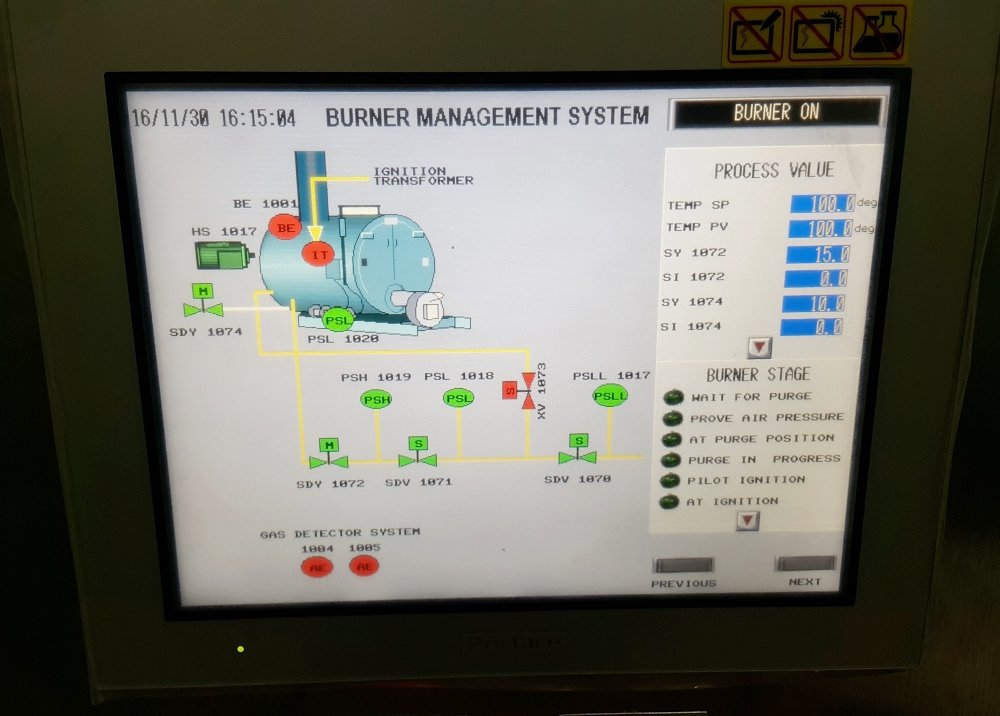

Specialist Services designed and delivered their first skid mounted process heater with SIL 2 rated Burner Management System for Zone II Hazardous Area installation

Specialist Services designed and delivered their first skid mounted process heater with SIL 2 rated Burner Management System for Zone II Hazardous Area installation This new solution offers various benefits for our clients, including:

This new solution offers various benefits for our clients, including:

In July 2014, Specialist Services was awarded a rental contract to deliver a Permit Office and a Tea Shack to support their client’s operation on an accommodation vessel in the North Sea for a period of 6 months.

In July 2014, Specialist Services was awarded a rental contract to deliver a Permit Office and a Tea Shack to support their client’s operation on an accommodation vessel in the North Sea for a period of 6 months.